Instrument Ball Valves

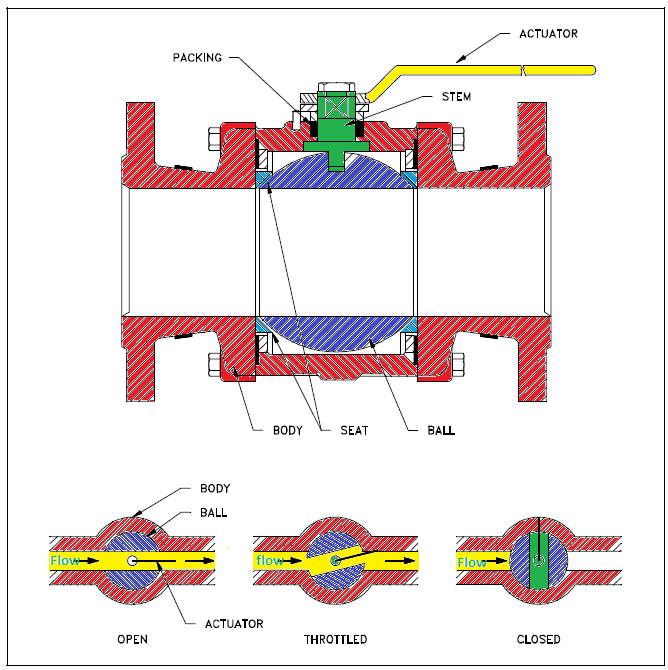

A Instrument Ball Valves is a rotational motion valve that uses a ball-shaped disk to stop or start fluid flow. The ball, shown in Figure 2, performs the same function as the disk in the globe valve. When the valve handle is turn to open the valve, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet. When the valve is shut, the ball is rotate so that the hole is perpendicular to the flow open of the valve body and the flow is stop.

Most ball valve actuators are of the quick-acting type, which require a 90° turn of the valve handle to operate the valve. Other ball valve actuators are planetary gear-operate. This type of gearing allows the use of a relatively small hand wheel and operating force to operate a fairly large valve.

Some ball valves has developed with a spherical surface coated plug that is off to one side in the open position and rotates into the flow passage until it blocks the flow path completely.

Seating is accomplish by the eccentric movement of the plug. The valve requires no lubrication and can be use for throttling service.

Advantages

A Instrument Ball Valves is generally the least expensive of any valve configuration and has low maintenance costs. In addition to quick, quarter turn on-off operation, ball valves are compact, require no lubrication, and give tight sealing with low torque.

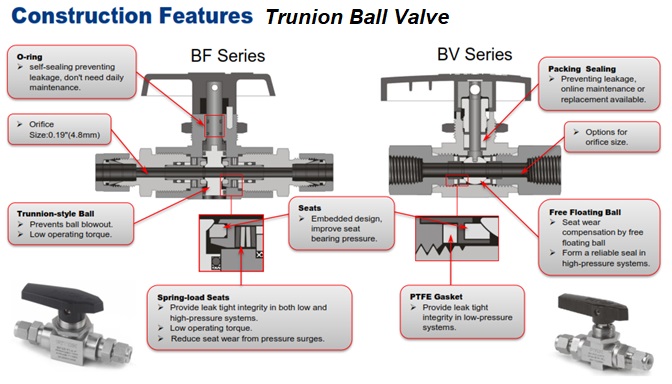

Trunnion Ball Valve

Disadvantages

Conventional ball valves have relatively poor throttling characteristics. In a throttling position, the partially exposed seat rapidly erodes because of the impingement of high velocity flow.

Port Patterns

Ball valves are available in the venturi, reduced, and full port pattern. The full port pattern has a ball with a bore equal to the inside diameter of the pipe.

Flow Pattern

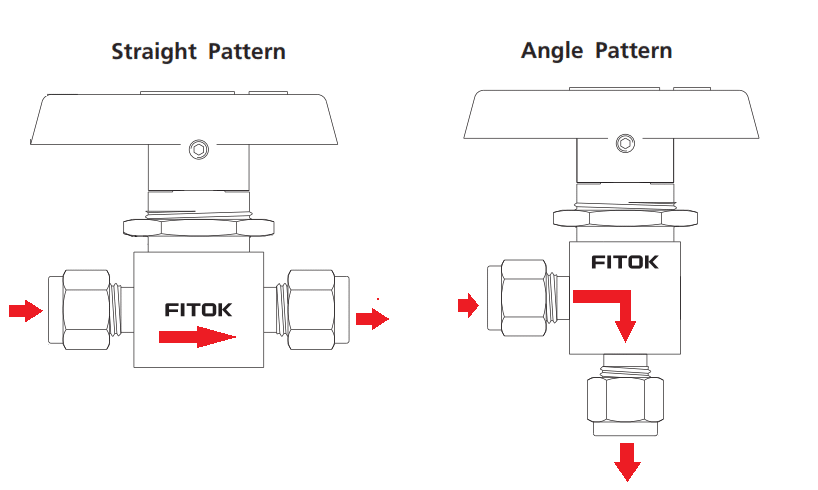

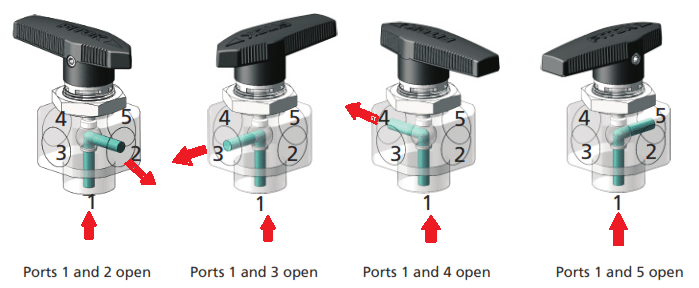

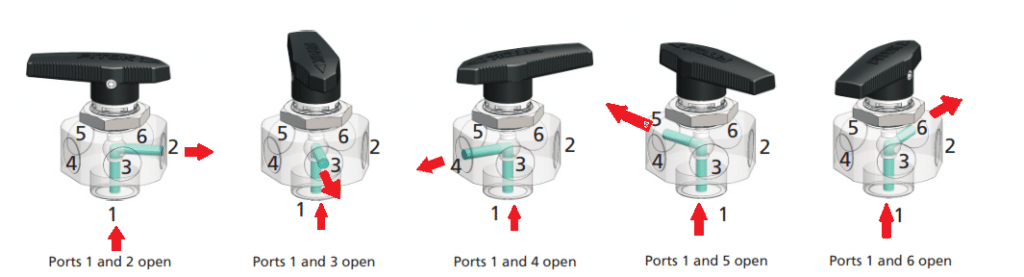

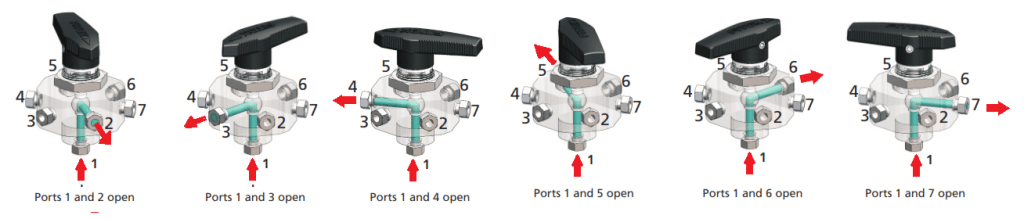

Ball Valve have two basic pattern design refer to application and function, that is Straight Pattern and Angle Pattern. Flow path is provide by function is 2-way, 3-way, 4 way and 5-way.

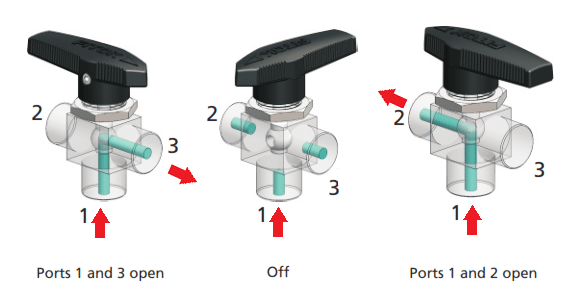

3-way Valves : This type of valve can connect one side port to the bottom port or shut off 3 ports. Switch between 0°, 90° and 180° positions with 180° rotation handle.

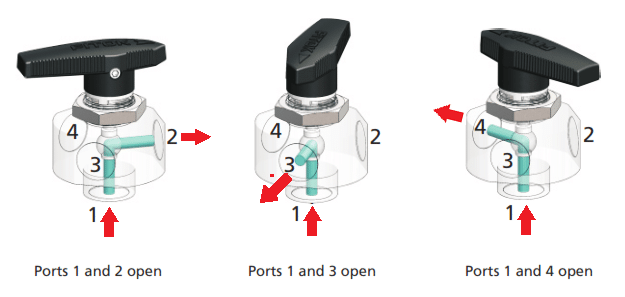

4-way Valves : This type of valve can connect one side port to the bottom port, and shut off other 2 side ports at the same time. Switching can be do in 120° increment with 360° rotation handle.

5-way Valves : This type of valve can connect one side port to the bottom port, and shut off other 3 side ports at the same time. Switching can be do in 90° increments with 360° rotation handle.

6-way Valves : This type of valve can connect one side port to the bottom port, and shut off other 4 side ports at the same time. Switching can be do in 72° increments with 360° rotation handle.

7-way Valves : This type of valve can connect one side port to the bottom port, and shut off other 5 side ports at the same time. Switching can be do in 60° increments with 360° rotation handle.

Valve Materials

Balls are usually metallic in metallic bodies with trim (seats) produce from elastomeric (elastic materials resembling rubber) materials. Plastic construction is also available. The resilient seats for ball valves is made from various elastomeric material. The most common seat materials are teflon (TFE), filled TFE, PTFE, PCTFE, PEEK, Nylon, Buna-N, Neoprene, and combinations of these materials. Because of the elastomeric materials, these valves cannot be use at elevated Temperatures. Care must be use in the selection of the seat material to ensure that it is compatible with the materials being handle by the valve.

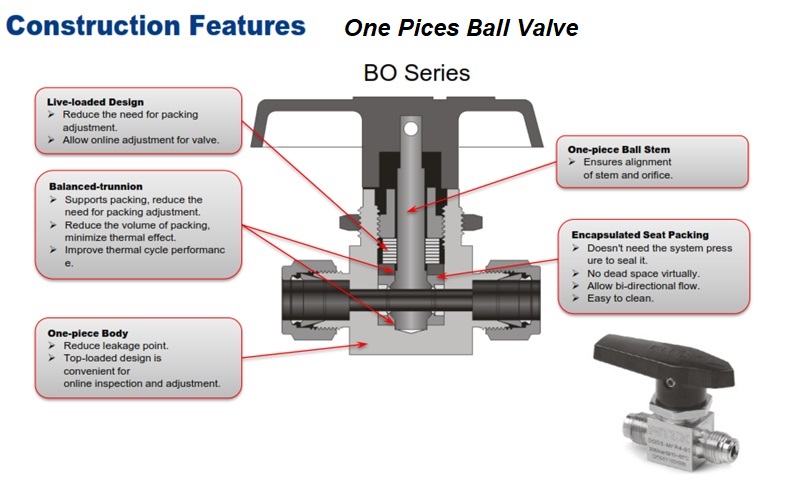

Ball Valve Stem Design

The stem in a ball valve is not fasten to the ball. It normally has a rectangular portion at the ball end which fits into a slot cut into the ball. The enlargement permits rotation of the ball as the stem is turn.

Ball Valve Bonnet Design

A bonnet cap fastens to the body, which holds the stem assembly and ball in place. Adjustment of the bonnet cap permits compression of the packing, which supplies the stem seal. Packing for ball valve stems is usually in the configuration of die-formed packing rings normally of TFE, TFE-filled, or TFE-impregnated material. Some ball valve stems are seal by means of O-rings rather than packing.

Ball Valve Position

Some ball valves are equip with stops that permit only 90° rotation. Others do not have stops and may be rotate 360°. With or without stops, a 90° rotation is all that is require for closing or opening a ball valve.

The handle indicates valve ball position. When the handle lies along the axis of the valve, the valve is open. When the handle lies 90° across the axis of the valve, the valve is close. Some ball valve stems have a groove cut in the top face of the stem that shows the flow path through the ball. Observation of the groove position indicates the position of the port through the ball. This feature is particularly advantageous on multi port ball valves.

End Connection

Tapered Pipe Threads End Connection

Tapered pipe threads are the most common end connection when valves must be connect directly to other equipment. Valves with a male pipe-thread inlet and a female pipe-thread outlet connection are often use as the isolation valve between the equipment and the system. When used with a pipe-thread inlet and a Swagelok tube fitting outlet connection, the isolation valve replaces the male connector fitting at the equipment and simplifies the system.

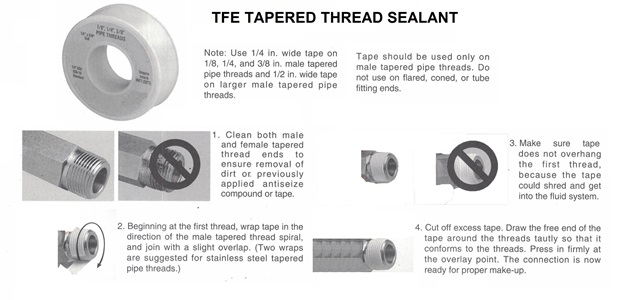

Pipe threads always need a sealant, such as TFE tape or pipe thread sealant, to fill the gaps between male and female threads for a leak-tight joint.

Tube Fitting End Connection

tube fitting end connections are use on the ends of valves in tubing systems to eliminate adapters and extra connections at the valve. This will reduce cost and minimize the number of potential leak points, along with making tubing systems smaller, easier to fabricate, and more reliable

Weld End Connection

Weld end connections are use when permanent, leak-tight connections are require. Small valves often have butt or socket weld connections for tubing. Larger valves generally have socket weld connections for tubing or pipe.

Please contact us if you need Ball Valve for your Instrumenn systems design.